*This post is sponsored by The Home Depot

Links below are affiliate links, clicking on them helps me keep this site going at no extra cost to you. Thank you for supporting my site.

The Home Depot offered me the Husky 4.5 Gal. Portable Electric-Powered Silent Air-Compressor to test out in my shop. Up until now I had used air compressors that took up too much shop space and/or were annoyingly loud. I was excited to compare its noise output and performance to systems I’ve used in the past. I was pleasantly surprised by the results and features that meet my needs in a small shop setting.

When I started building up my shop, one of the tools I thought I would need was a large tank air compressor tucked in the corner of my shop. I used the compressor to power pneumatic nailers and blow dust off my projects. My first air compressor was a very loud 30-gallon Craftsman compressor. While it worked as it should, I never really used it to its full capacity. It ended up being a waste of precious floor space and would constantly turn on while I was recording video. Unfortunately, I don’t have pictures of the old beast. My second air compressor was a small 6-gallon Porter Cable pancake compressor. While the compressor took up a much smaller footprint, it was still very loud comparatively to its size. I dreaded firing up the compressor.

The Husky 4.5 Gal. compressor claims to operate at less than 65 dB (decibels). To measure the decibel level of the Husky compared to my old pancake compressor, I used a decibel sound meter app on my tablet. The sound meter was not calibrated and I wouldn’t trust it to give me the most accurate reading. However, it did give me an understanding of how much quieter the Husky was compared to my Porter Cable. The Husky output a sound level of approximately 66 dB, while the Porter Cable output a sound level of approximately 80 dB. For context, 80 dB is 10 times as loud as 70 dB (decibels are measured on a logarithmic scale). 60 dB is equivalent to the sound level of conversation in a restaurant. Whereas 80 dB is equivalent to the sound level of freight train. The Husky compressor is significantly quieter than the Porter Cable pancake compressor (13 dB quieter).

The Husky 4.5 Gal. compressor output a sound level of 66 dB.

The Porter Cable pancake compressor output a sound level of 80 dB.

The Husky 4.5 Gal. compressor also features a twin stack tank. While the Husky is smaller in tank capacity than the Porter Cable (4.5 gallons vs. 6 gallons), it is much heavier. The Husky weighs in at 71.5 lbs versus the Porter Cable weighing in at 30 lbs. However, the weight of the Husky does offer an advantage. The motor is mounted forward of the tanks and offers a stable platform. It is conducive to a size and shape that can be transportable with wheels and a handle. The result is a compressor that vibrates less. I’ve actually had the Porter Cable rattle across my assembly table. Thankfully, I noticed it before it vibrated off the assembly table.

The twin stacks on the Husky air compressor offers a form factory that’s conducive to transportability.

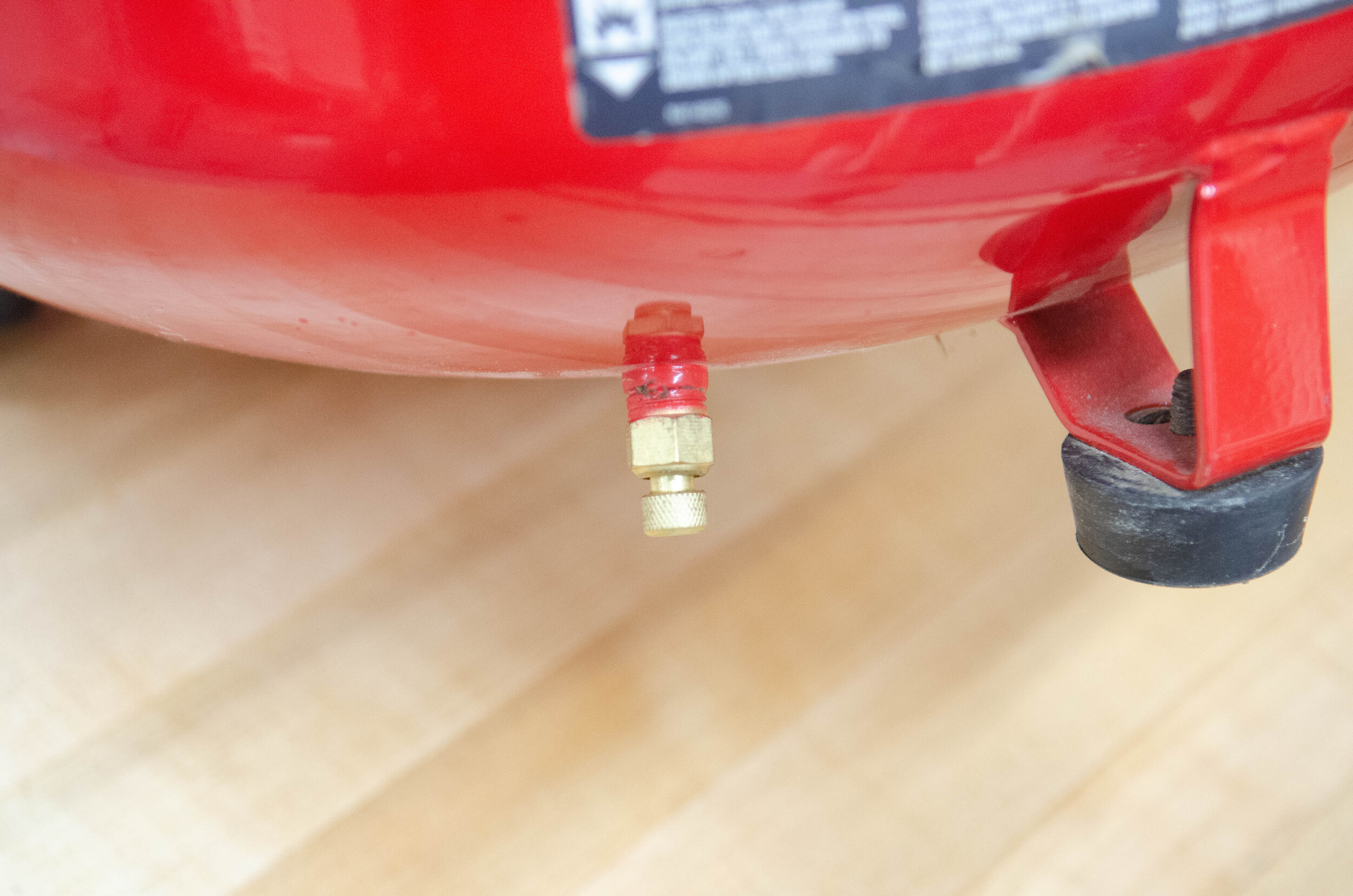

It is important to drain your compressor after use. Compressed air accumulates condensation, and over time that condensation can result in rust forming on the inside of your compressor tanks. The Husky compressor features a ball valve to easily drain the tanks. The Porter Cable has a screw valve, which is a little harder to use, especially under load. Also, you need to be careful not to unscrew the valve too much or else it will go flying off of your compressor tank. Don’t ask me how I know this.

The ball valve at the bottom of the Husky compressor tanks.

The screw valve at the bottom of the Porter Cable compressor tank

The build quality on the Husky compressor is great. The tubular steel cage protects the motor and makes for a rigid platform to mount all of the components. I like the location of the dials, and hose connectors. The regulator is large making it easy to adjust tank pressure. The on/off switch is somewhat hidden on the side of the machine. While it is colored red, it’s little hard to notice at first.

The regulator, dials, and connectors are well placed at the top front of the compressor.

The on/off switch is tucked on the side of the machine preventing it from being accidentally switched on and off, but is a little hidden at first glance.

The most important aspect of the compressor is how it performs based on air delivery. Husky compressor delivers 3.0 SCFM (standard cubic feet per minute) at 90 psi (pounds per square inch), and 4.0 SCFM at 40 psi. The maximum pressure the Husky compressor can deliver is 175 psi. At that air flow the Husky air compressor can handle a pin nailer, brad nailer, finish nailer, upholstery nailer, crown stapler, roofing nailer, and framing nailer with an operating range of 90-130 psi. The compressor can also deliver enough air for a blow gun, grease gun, and tire inflator.

I’ve been able to use the Husky 4.5 Gal Silent Air Compressor for the last 2 months on several CNC projects, and two furniture projects. I’ve also used the air compressor to inflate my vehicle and lawn tractor tires. The Husky air compressor has been able to keep up with the tasks that I do in my shop and home without the high level of noise output.

Using compressed air to power my pneumatic nailers.

Using compressed air to blow dust and debris off of my furniture projects prior to applying finish.

Inflating my lawn tractor tires during the cooler fall season.